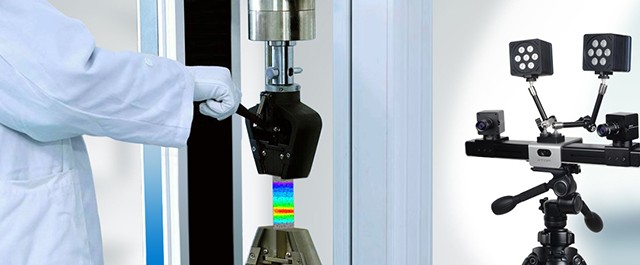

XTDIC-Micro 3D Microstrain Measurement

The XTDIC-Micro microscopic application measurement system combines optical microscopy with DIC digital image correlation technology to meet the needs of nanometer-level precision measurement.

Technical Advantages

- Obtain three-dimensional coordinates, displacement, and full-field strain data.

- 3D visualization of measurement results.

- Suitable for all materials.

- Fast, simple, and high-precision system calibration.

- Freely adjustable measuring area: 1–10 mm.

- Strain measurement range from 0.01% to over 500%.

- Flexible and easy-to-use triggering functions.

Application Scope

- Microstructure and strain analysis at micrometer and nanometer scales.

- Material testing including Young’s modulus, Poisson’s ratio, and elastoplastic properties.

- Strain calculation, elasticity assessment, component size measurement, and nonlinear change detection.

- Advanced materials such as CFRP, wood, PE-containing fibers, metal foam, and rubber.

- Behavior analysis of homogeneous and non-homogeneous materials during deformation.

- Component testing for displacement and strain measurement.

- Microscale dynamic strain measurement such as fatigue testing.

- Biomechanics including bones, muscles, and blood vessels.

- Fracture mechanical property analysis.

- Nonlinear change detection.

Technical parameters

Similar Products

XTOP3D Photogrammetry

XTDP-C Series 3D optical photogrammetry system.

XTDIC-FLC 3D Sheet Forming Limit Measure...

The XTDIC-FLC system uses Digital Image Correlation (DIC) to analyze sheet metal deformation in cupping tests. It captur...

Tube Qualify

3D Optical Tube Inspection System

XTDIC-CONST 3D Strain Measurement

The XTDIC-CONST system is a non-contact optical tool. It uses Digital Image Correlation (DIC) for full-field strain meas...

XTDIC-STROBE 3D Dynamic Measurement

The XTDIC-STROBE 3D dynamic measurement system uses a high-resolution, high-speed digital camera to capture the motion a...