XTDIC-CONST 3D Strain Measurement

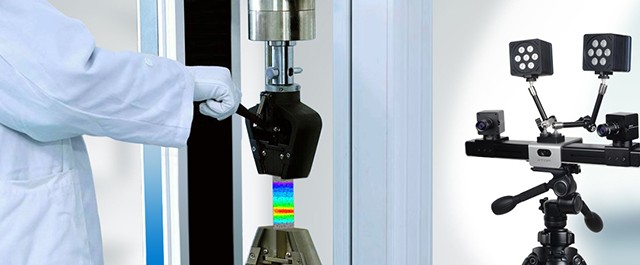

The XTDIC-CONST system is a non-contact optical tool. It uses Digital Image Correlation (DIC) for full-field strain measurement. Highly versatile, it handles diverse test rates and measurement ranges.

Full field measurement

The measurement is not limited to a single point, and the full-field three-dimensional profile, displacement and strain results can be obtained.

Non-Contact Measurement

Non-contact measurement, adapts to various materials, not limited by sample geometry.

Simple and Easy to Use

Full-field strain calculation and result display can be performed in real time, and real-time output of calculation results is supported by UDP and other methods.

XTDIC-CONST Application

Materials research and parts measurement

Materials Research

The XTDIC-CONST full-field strain measurement system can analyze the mechanical properties and behavior of materials under a wide variety of testing environments. It can be seamlessly integrated into existing measurement environments, testing benches, and testing machines. Utilizing a non-contact measuring head, it can measure the full-field three-dimensional strain and deformation of soft and hard materials under both mechanical and thermal loading conditions. It can replace traditional extensometers and strain gauges, enabling real-time three-dimensional surface deformation analysis.

Currently, XTDIC-CONST has been widely used in the measurement of material mechanical properties and is a measurement solution that has been widely recognized and praised in the industry.

-

Full-field strain distribution

-

Stress-strain curve

-

Young's modulus

-

Poisson's ratio

-

N value & R value

-

Tensile test

-

Shear test

-

Three-point bend/four-point bend

-

Fatigue testing...

Finite element analysis and simulation verification

In the design and manufacturing of new products, manufacturers are increasingly using finite element analysis software for simulation analysis to optimize and improve product performance and manufacturing processes. XTiDC-CONST can compare and analyze actual test results with theoretical data from finite element simulation software, effectively improving simulation tools and processes, accumulating more data for projects, and helping to accelerate product launches.

-

Compare simulated data with actual measurement results (strain, displacement, etc.)

-

After measuring the material properties, they are input into the simulation software as parameters.

-

Includes mesh optimization functionality for CAD conversion, used in finite element analysis.

-

Digital simulation verification

-

The measurement is not limited to a single point, and the full-field three-dimensional profile, displacement, and

strain results can be obtained.

Non-contact measurement, adapt to various materials, not limited by sample geometry.

Full-field strain calculation and result display can be performed in real time, and real-time output of calculation

results is supported by UDP and other methods.

Full field measurement

Non-contact measurement

Real-time measurement

Similar Products

XTOP3D Photogrammetry

XTDP-C Series 3D optical photogrammetry system.

XTDIC-Micro 3D Microstrain Measurement

The XTDIC-Micro microscopic application measurement system combines optical microscopy with DIC digital image correlatio...

XTDIC-FLC 3D Sheet Forming Limit Measure...

The XTDIC-FLC system uses Digital Image Correlation (DIC) to analyze sheet metal deformation in cupping tests. It captur...

Tube Qualify

3D Optical Tube Inspection System

XTDIC-STROBE 3D Dynamic Measurement

The XTDIC-STROBE 3D dynamic measurement system uses a high-resolution, high-speed digital camera to capture the motion a...